Description: Conservation tillage embraces one principle of conservation agriculture; "Minimum soil disturbance". It includes practices that keep the disturbance of the soil and loss of organic matter to a minimum, reducing soil and water losses.

Introduction

Soil tillage comprises all the physical, mechanical, chemical or biological actions conducted to prepare the seedbed for seed germination, emergence and establishment, root development and crop growth.

Conservation tillage embraces one principle of conservation agriculture "Minimum soil disturbance" and includes practices that keep the disturbance of the soil and loss of organic matter to a minimum, reducing soil and water losses. Mostly, the soil is not turned using ploughs.

No or minimal mechanical soil disturbance

Direct seeding involves growing crops without mechanical seedbed preparation or soil disturbance after the harvest of the previous crop. The term direct seeding is used synonymously with no-till farming, zero tillage, no-tillage, direct drilling, etc.

No-tillage involves slashing the weeds and previous crop residues or spraying herbicides for weed control, and seeding directly through the mulch using direct seeding implements. All crop residues are retained, and fertiliser and amendments are either broadcast on the soil surface or applied during seeding.

Soil cover with mulch or stubble plays an important role in conservation tillage. Mulch reduces evaporation losses, increases infiltration, and helps the building-up of biological micro flora and fauna/soil organic matter (SOM), thus improving long term soil structure and fertility. A mulch cover can reduce weed development, but also increase pest and disease infestation. For more information please refer to section 'mulching'.

Effects:

- Minimal destruction of soil structure through pulverisation, compaction and/or plough pan development

- Slower mineralisation of soil organic matter through less exposure to climatic elements and soil micro and macro fauna

- No disturbance of worms and other soil inhabitants, maintained soil biodiversity and balanced activity and food web in the soil including natural predation.

- Better infiltration and circulation of air and water into and through the soil profile through maintained bio-pores and vegetative cover and optimal rooting

- Reduced evaporation from bare soil surfaces

- Soil regeneration rate through mineralisation and decomposition and re-structuring higher than soil degradation through loss of porosity and soil particles (erosion) and loss of plant nutrients (fertility)

- Improved nutrient retention and availability for plant growth and reduced leaching of nitrogen and other nutrients

- Improve timely field operations

How is it achieved? (Means and practices)

- No ploughing, discing, harrowing etc.

- Use of direct seeding through crop residues

- No crop residue burning

- No incorporation of crop residues into the soil

- Permanent bed planting/planting station ridgeline/rip line

- Use of crop rotations, balanced biodiversity and pesticides for weed/pest control instead of ploughing or using high rates of chemicals that endanger soil life and disturb the soil and ecological processes including the hydrological cycle and water quality

The use of the different systems for conservation tillage depends on the primary objectives, farm equipment and power available, physical condition of the land and the crops grown. Some tillage systems are designed for using animal- or tractor-drawn equipment, other are suited for hand labour. Conservation tillage systems common in East Africa include:

- No-till or zero-tillage

- Reduced or minimum tillage

- Pitting systems

- Stubble- and residue-mulch tillage

- Ridge and furrow

Conservation tillage is part of the concept of conservation agriculture, whose basic principles are little or no soil disturbance, diverse crop rotations and permanent soil cover.

No-Till or Zero-Tillage Systems - Conservation Tillage

For more information see: Conservation tillage

No-tillage is generally defined as planting crops into soil that has remained untilled after the harvest of the previous crop.

Conservation tillage includes the WHEN and HOW this tillage is done. The "when" basically refers to the moisture-state of the soil. Conservation tillage takes into account both environmental and tillage factors .This system involves opening a narrow slot only wide and deep enough to obtain proper seed coverage and with at least 30% mulch cover. Permanent, continuous no-tillage should follow, while the soil should remain covered by crop residues or green manure cover crops. Crop residues should remain undisturbed on the soil surface after seeding.

No-tillage and reduced tillage have been used since ancient times by indigenous cultures. This was because tillage to any depth required more energy and power than was generally possible with hand labour. The ancient Egyptians and the Incas in the Andes of South America used a stick to make a hole in the ground and place seeds by hand into the unprepared soil (Derpsch, 1998). Even today in some parts of the world that use shifting cultivation, seed is dropped into a hole after clearing the forest by burning. Tillage, indeed, greatly aided the enhancement of food production by creating a seedbed for easier planting and by controlling competition by weeds. However, tillage also accelerated soil loss and soil structural degradation hence leading to the current food shortage and persistent crop failure in most parts of Sub Saharan Africa.

There are a number of reasons for adopting no-tillage in addition to the effects listed above the following are the most attractive to farmers;

- Reduction in the cost of production: For instance, production costs per acre (0.405 ha) of soybeans under no-tillage are reduced by US$ 27.00 in Argentina, by US$ 14.18 in the USA and by US$ 11.50 in Brazil (Derpsch, 1998). According to FAO recent studies have shown that practicing conservation tillage leads to:

- Less labour and farm power

- Up to 60% fuel savings

- Up to 50% savings in tractors

- Up to 40% savings in tractor size

- Up to 3 times longer tractor-life

- Reduction in machinery capital

- Timely farm operation is easily achieved through no till. Farmers are able to plant well in good time since the focus on land preparation is mostly neither intensive nor subjective. Studies have shown that timely planting contributes up to 40% of the yield hence the ability of Conservation Agriculture to increase yield is largely drawn from this principle.

Benefits and constraints of No-Tillage

Some of the benefits of no-tillage include:

- Prevention of soil erosion

- Prevention of soil compaction

- Preservation of soil structure, soil aggregates and macro-pores

- Improvement of soil moisture and water use efficiency through mulching

- Promotion of beneficial organisms such as earthworms

- No-till mulching enhances soil microbial activity, transfers organic matter to the soil improving its nutrient status

- Less inputs of fuel, energy and labour

Despite the wealth of research information in Africa showing the benefits of no-tillage, this farming system is not yet extensively practised (Lal, 1973, 1983)

The ecological constraining factors for spreading no-tillage in Africa are:

- Effects of climate change resulting in low precipitation with low biomass production

- Short growing seasons

- Sandy soils with tendency for compaction

- Soils at risk of waterlogging

Where no-tillage is not possible, the second best choice is minimum tillage.

Steps to No-Tillage Adoption

Before adoption of the no-tillage system following factors must be consider:

- Farmers must improve their knowledge about the system (especially weed control) before trying the technology on their farms

- The change to no-tillage should be planned at least one year before implementation

- Plan to acquire no till implements (direct seeders) and obtain proper orientation on their utilisation. The implements so acquired should match the available farm power.

- It is advisable to start with a small portion/section and advance with time (e.g. 10% of the farm)

- Soil tests should be done, and nutrient deficiencies corrected, aiming at a balanced nutrient and pH status. If soils are acidic, farmers should apply small quantities of lime each year (instead of large amounts only once)

- Avoid soils with bad drainage. It is known that no-tillage does not work on badly drained soils or if soils suffer from water-logging

- Level the soil surface, as uneven surfaces make exact seeding impossible

- Eliminate soil compaction

- Use crop rotations and green manure crops, these are basic in no-tillage system

- Produce the highest amount of mulch cover possible. Choose crops varieties/species with higher biomass than others ( e.g. maize instead of beans) and include green manure cover crops in the rotation. Crop residues and green manures must be left on the soil surface, being incorporated biologically into the soil as they decompose

- Buy a no-till seeding (planter) only after having met all requirements mentioned above

- Learn constantly and stay up to date with new developments

Reduced or Minimum Tillage Systems

This refers to those tillage practices where by minimum or no disturbance is effected on the soil for purposes of crop production. It involves the making of furrows or holes where seed is planted. The rest of the field remains undisturbed and crop residue is left on the surface. This practice reduces soil erosion; causes build up of organic matter in the soil, hence better chemical and physical soil fertility. Minimum tillage also implies reduced labour, energy, and reduced time demand in land preparation. Hence, cropping can be done in time at less cost. In most commercial farming, the weeding in minimum tillage systems would be done using herbicides.

It differs from traditional tillage by having one or more of the following components:

- Less operations

- Less soil disturbance

- Requires less power

- Seedbed is prepared only where the seeds are planted

- Residues remain on topsoil (are not buried)

- Reduced use of several types of equipment

Only the necessary operations to optimise soil conditions for seed germination and crop establishment and growth are performed: minimise human and machine traffic and thus avoid soil compaction and destruction of soil structure; to avoid soil erosion; to conserve soil moisture; and to use less labour and mechanical energy.

Minimum tillage practices include:

1) Dibble stick planting

|

| Dibble stick planting |

|

© ACT, Kenya

|

Planting stick or machete can be used to create holes to plant the seed in an un-ploughed field with stubble/crop residue. The cut hardwood stick from the bush is sharpened at one end and used to make planting holes. The holes are made in lines at evenly spaced intervals that make it easier to weed and apply fertiliser or manure.

2) Disc-plant (stubble-harrowing)

This tool is used to loosen the soil, chop up crop residues and cut weeds. Afterwards planting is done without further soil disturbance and the crop residues are left on the surface

3) Strip and spot tillage

This involves scraping out shallow planting holes in un-ploughed soil, sowing the seed in the holes, then covering. This approach is common throughout the Sahel (Mali, Niger, Chad, and other countries). The only equipment needed is the hand hoe (Jjembe) and a planting stick. You can plant in the dry or just after the rains. The following are the steps involved:

- Dig small shallow holes at the correct distance from each other. Make the holes just deep enough to plant the seeds.

- Put the correct number of seeds in the hole, and cover them with soil.

- About 2 weeks after the crop emerges, use a stick to make a hole about 10 cm away from each plant. Put fertiliser into the hole.

Advantages

- Less labour requirement compared to conventional cultivation.

- More attractive to vulnerable households due to labour factor and not a huge chunk of land is required.

- Planting done on time

- Do not require expensive equipment - just a hoe and a stick.

Disadvantages

- Weed control may be difficult

- Do not break a hardpan caused by hoeing at the same depth year after year.

- Crop roots may not grow well as with planting basins, and less water will infiltrate into the soil.

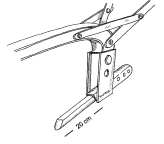

4) Ripping

|

| Ripping |

|

© ACT, Kenya

|

A ripper is a chisel-shaped implement pulled by animals or a tractor. It breaks up surface crusts and opens a narrow slot or furrow in the soil, about 5 - 10 cm deep.

Many conservation tillage systems use a ripper with a single chisel fixed to a plough or ridger frame. In ripping, only shallow parallel furrows are cut using a ripper without disturbing the soil between the planting rows. The ripper should cut regular lines to facilitate subsequent weeding with ox-drawn weeders. Planting is usually done at the same time. The distance between the furrows depends on the recommended spacing for the crop. Ripping can reduce or eliminate the need for ploughing.

The ripper is faster than ploughing, as tillage is limited to only a thin opening for planting. Because of this narrow working width, pulling a ripper requires about half the draught force of that needed for pulling a conventional single-furrow plough.

The ripper is smaller and lighter than a plough, and is easier to operate. The farmer can also use smaller animals, or animals that may be weaker at the end of the dry season. The ripper is also cheaper to buy and cheaper to maintain. As a result of these advantages, the farmer can work larger acreages each season, and achieve timeliness in operations, thus taking advantage of the early rains. This is important, especially in seasons of lower-than-normal rains or, generally, for marginal-rainfall zones. The weed problem can be serious in a rip tillage system. Therefore, action should be taken to lessen the

problem over the longer term. The ripper (e.g. the Magoye ripper) is a useful weeding tool.

Advantages

- Ripper attachments fit on a normal plough beam hence cheaper than complete implements.

- Can be used to make planting slots in dry soil allowing early planting.

- Disturbs the soil less than ploughing hence reduces soil erosion and encourages water infiltration into the soil.

Disadvantages

- Difficult if there is a lot of residue on the surface because the residue wraps around the ripper shaft.

- Disturbs up to 30% of the soil surface.

- Quite difficult to use on fields with tree stamps.

Case study 1: Study on effects of ripping in Wanging'ombe Village Southern Tanzania

Nineteen farmers of Wanging'ombe Village were introduced to ripping and improved soil cover with Mucuna in 2001. Five of these have doubled maize grain yield and increased sunflower production by 360% compared to conventional mould board tillage (Table 5). However, there is confounding of the treatments, since the variable was not only tillage technique and cover crop, but also use of industrial fertilisers. The other 14 farmers could not attain similar yields because they could not afford to buy industrial fertilisers.

Farmers in Mayale Village reported that the performance of crops and crop yields were more stable since the adoption of Conservation Agriculture (CA) technologies. They were able to harvest a maize crop from ripped plots in 2001 when rainfall was merely 560 mm albeit a substantial (67.2%) labour saving (Table 7). Ripping enabled capture of rainwater along with in situ storage and cover crops (especially Mucuna) provided soil surface mulch for moisture retention, thus increasing crop stability against drought stress.

Table 1: Mean* maize and sunflower yields under CA (ripping and mucuna) practices in Wanging'ombe and Mshewe Wards

| Ward | Crop | Conventional cultivation** | CA practices*** | Increase (%) |

| Wanging'ombe | Maize yield (kg/ha) | 1125 | 2250 | 100 |

| Wanging'ombe | Sunflower yield (kg/ha) | 750 | 2700 | 360 |

| Mshewe | Maize yield (kg/ha) | 1500 | 2900 | 93 |

| Mshewe | Sunflower yield (kg/ha) | 625 | 1500 | 140 |

* Means of 5 CA FFS members in Wanging'ombe and 8 in Mshewe.

** Planting behind the plough at the start of the rains followed by two hand hoe weedings.

*** Opening of planting furrows with ox-drawn ripper on un-ploughed fields prior or at onset of rains, hand planting of seeds, two weedings with ox-cultivator.

Table 2: Maize grain yield on farmer trial plots at Mayale in 2001. Means of 7 farmers.

| No. | Treatment | Field Capacity (hahr-1)*1 | Labour input (Manday/ha-1) **2 | Maize grain yield (kgha-1) |

| 1 | Ox ripper | 0.0719 a | 31.6 b | 1344 a |

| 2 | Ox ripper planter | 0.0721 a | 29.6 b | 1059 b |

| 3 | Ox tied ridges | 0.0194 b | 102.6 a | 1021 b |

| 4 | Ox plough | 0.0211 b | 96.2 a | 1066 b |

| Grand mean | 0.0461 | 65.0 | 1122 | |

| Coefficient of Variation (%) | 29% | 11% | 22% |

*1 Ability in terms of how many hectares can be worked in 1 hour by the ox-team (2 operators and a pair of oxen) using the respective implement.

**2 Labour input for the planting operation (i.e. opening of planting furrow, placement of seed, fertilizer and seed covering).

Source: Mkomwa et. al. 2002.

More labour saving benefits would be reaped if the full ripper and planter attachment were used, since it is possible for one person to open up the land and plant seeds. The ripper planter was not the choice of farmers, as it was more expensive than the ripper (Tsh 190,000 compared 120,000) and seed metering, using farmer (un-graded) seeds, was uneven.

Case study 2: Makundi's success story

Pastor Humphrey Makundi from northern Tanzania has one acre in his nearby farm. Normally he would harvest 6 bags of maize. He ripped with improved maize seeds intercropped with lablab. He also established contours that reduced runoff on his cattle pasture. He managed to harvest 10 bags that season [2004]. In the following season he rented 4 more acres and harvested 10 bags of maize from each acre, totalling 50 bags in one season.

Pitting systems

Matengo pits

Structures called "matengo" pits are used in the Southern Highlands of Tanzania. The pits can be up to 1m x 1m and 30 cm deep, but the actual size is determined by depth of the soil and ease of digging. The pits are laid out on sloping land forming a grid to cover the entire surface. Soil taken from the pits is used to form ridges around the pits.

Crops are grown on the ridges and the weeds and crop residues are thrown into the pits. A rotational system is usually practiced using crops such as maize, beans and sweet potato, and the pits are regularly moved and new ridges built where the organic matter has accumulated. The pits also serve as structures to conserve water.

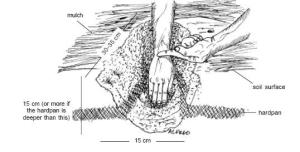

Zai basins

|

| Zai basins |

|

© ACT, Kenya

|

"Zai" basins are used in semi-arid areas to concentrate manure and runoff into basins or pits where the crops, e.g. sorghum, are planted. Zai pits have traditionally been used in the dry regions of Burkina Faso and Mali in West Africa. The pits are about 15-20 cm deep and 30 cm in diameter, with 1 m between the rows.

Topsoil from the excavation is mixed with manure and put back in the pit where a few cereal seeds are then planted. The pits also concentrate rainfall runoff around the plants, thus improving moisture supply to the roots.

Planting holes

|

| Planting holes |

|

© ACT, Kenya

|

There are at least two systems being used in certain areas of Kenya and Tanzania. One of these is a system of planting 5 or 9 maize plants in large holes of about 1.5 m diameter (4 or 8 plants along the edge and 1 in the middle, respectively). The soil is first dug out to sufficient depth to break through any hardpan, if present, and allow free drainage. The topsoil is returned, together with manure, and the remaining soil placed around the hole to catch rainfall and concentrate it where the plants are growing.

The second system, developed in Dodoma, is known as "chololo" pits. The holes are similar to the above but only about 25 cm deep and 30 cm in diameter, being spaced at 60 cm within the rows and 90 cm between rows. The rows are arranged roughly on the contour. The soil from the pits is put on the lower side of the pit, forming a half-moon shape that traps runoff into the pit. Planting is done in the pits.

Further systems: Stubble- and Residue-Mulch tillage, Ridge and furrow

Stubble- and Residue-Mulch tillage

This involves cutting the roots of weeds and other plants and leaving the crop residues on the surface or mixed into the top few centimetres of the soil.

The cutting is usually done with a tined implement with blades or sweeps attached to the tines to uproot or undercut the weeds. The result is to reduce erosion and to conserve water by reducing runoff, and also to regulate soil temperature and increase soil fertility and organic matter content. Equipment used for planting must have special furrow openers to avoid clogging with trash.

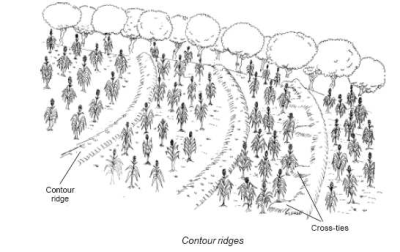

Ridge and furrow systems

Simple or tied ridging cultivation results in better soil and water management than conventional ploughing.

The ridges and furrows help to regulate runoff flow, to increase water infiltration and storage and reduce soil and nutrient losses. The system is most suitable for gentle slopes, especially in marginalrainfall areas. Row crops are planted either on the ridge top, in the furrow or along both sides of the ridge.

A ridger can be used for ridge and furrow cultivation. Sometimes a discontinuous furrow is made by making cross-ties that interrupt water flow in the furrow, thus creating a series of basins or pools to retain water for a while and to promote slow seepage. This is called tie-ridging. The ridges may be maintained for several seasons to reduce construction work. Usually seedbed preparation and planting are done in one combined operation.

A system of broad ridges (beds) and furrows has been found to be useful on vertisols (black-cotton soils) because it allows drainage and facilitates cultivation. Modifications of the animal-drawn mouldboard plough have been used for making broad ridges for growing wheat and other crops on such soils in Ethiopia and Kenya.

|

| Tied ridges for water conservation |

|

© C. Gachene and G. Kimaru, RELMA, 2003

|

|

| Contour ridges |

|

© ACT, Kenya

|

Equipment

Hand tools

The following hand tools will be mostly utilized in conservation tillage:

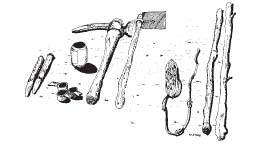

|

| Hand tools |

|

© ACT, Kenya

|

- A hoe or jembe is a common household farm tool in East Africa. It should be as narrow as possible (10 cm wide is good size).

- A long string: Used to measure off the correct distance. Tie knots in the string at the plant spacing are preferred but bottle tops could also be used to demarcate the spacing interval.

- Two sticks to mark the rows and to make sure the rows are parallel.

- Two strong pegs to hold the string at both ends.

- Fertiliser cups to apply fertiliser or lime.

- An empty drink can to apply manure.

-

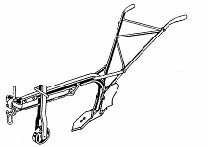

Rippers

The most commonly used ripper in East Africa is Mogoye ripper which originated from Zambia. This is a single tine implement used for opening furrow for insitu water harvesting. The opened furrow is also used for planting. The implement uses the same mould board plough frame with only the mould board attachment being replaced by ripper attachment. The implement can therefore be drawn by oxen, donkey or horse. The implement is designed to fit in all plough frames hence a farmer with ox plough will not incur any extra cost apart from acquiring the ripper attachment.

|

| Rippers |

|

© ACT, Kenya

|

|

| Ripper drawn by oxen |

|

© ACT, Kenya

|

|

| Ripping with donkey |

|

© ACT, Kenya

|

|

|

|

Sub-soiler |

|

© ACT, Kenya

|

-

Sub-soilers

Sub-soiler is an implement used for breaking the hard pan/plough pan. There exist various types of sub-soilers depending on the farm power available. Tractor powered sub soiler commonly used in large scale farms can either be single or double chiselled tine. The animal powered sub soiler consists mainly of a single chisel tine which penetrates the soil surface breaking the hard pan/plough pan. The implement uses the same mould board plough frame with only the mould board attachment being replaced with sub soiler attachment. The implement just like the ripper can be drawn by oxen, donkey or horse. The implement is designed to fit in all plough frames hence a farmer with ox plough will not incur any extra cost apart from acquiring the sub soiler attachment. Sub-soiling is a remedial measure which is not undertaken every season hence farmers should only use sub soiler in fields with hard pan/plough pan.

|

| Sub-soiler breaking the plough pan |

|

© ACT, Kenya

|

Planting implements

|

| Jab planter |

|

© ACT, Kenya

|

-

Jab planter

This is a hand/manually operated direct planting implement with ability to sow both seeds and fertiliser simultaneously. The implement exists in many models depending on the manufacturing company but the operational principle is normally the same. There exists a single hopper and a double hopper jab planter. The implement is able to plant variety of crop seeds depending on the selected seed plate and the jab plant type.

|

| Animal drawn direct planter |

|

© ACT, Kenya

|

-

Animal drawn direct planter

This is an animal powered implement with the ability to directly sow seeds and fertiliser simulteneouly. It requires an operator to direct the planting operation while the pulling is done by trained oxen, donkey or horse. The implement also exists in many models depending on the manufucturer however the operational principle for seed and fertiliser distribution largely remain the same. The implement unlike the jab planter has provision to plant a wide range of seed crops due to the presence of several sets of seed plates which only require replacement during calibration process.

|

| Tractor drawn direct seeder |

|

© ACT, Kenya

|

-

Motorized/tractor drawn direct seeder

This is a tractor powered direct planter with the ability to sow both crop seeds and fertiliser simultaneously in several rows. The implement exists in several models and sizes depending on the manufacturing company and the tractor power available respectively. It is able to plant variety of crop seeds due to availability of several sets of seed plates. Once calibrated and set accordingly, the implement is able to maintain uniform spacing throughout the farm.

Case study 3: Case of a large scale CA farmer in Laikipia Kenya "Lengetia farm"

The farm is located in Lamuria division where it boarders large scale ranches inhabited with wild game and livestock ranching. They own 680 acres of land and rent a total of 4200acres from his neighbouring ranch known by the name Ol Pajeta. This is an ASAL region where rainfall is not reliable and ranges between 750 - 800mm. The farm falls within zone 5 (Lower Highland Ranching Zone). The farmer grows wheat and barley as main crops while canola and a little sun flower as rotational crops.

From 1997-2002, Mr. Sessions was practicing conventional tillage for production of wheat and barley on 1000 acres. He faced a myriad of problems ranging from reduced soil fertility, high fertiliser requirement, and high cost of farm machine operations due to increase in oil market, increased soil erosion, emergence of plough pans and finally the decline in wheat market due to trade liberalisation within COMESA countries. This situation therefore made his production cost high to the extent that his produce could no longer become competitive. In 2000, he saw an Australian no till planter in one of his family friend's farm. After getting explanation about its use and importance combined with knowledge he had acquired from reading several agricultural magazines and journals on tillage, he decided that he needed to acquire such a machine at whatever cost. In 2002, he had an Australian pneumatic direct seeder assembled in his farm by the manufacturer's mechanics that travelled purposely to ensure that the machine was operating in good order and the user was well versed with its operation manual. He immediately embarked on growing wheat and barley using conservation agriculture and increased crop acreage from 1000 - 1500 acres by the year 2003. In 2004 he increased the acreage under CA again from 1500-4700 acres which excluded 420 acres which he rented in Timau area of central division. Until now, he is perhaps one of the CA adopters in the district who is able to exploit the advantages which come with its adoption.

The benefit of adopting CA did not come immediately after acquisition of the machines. Because he understood the process of practicing the new farming technique, he immediately embarked on restoring the soil biomass by accumulating and spreading the crop residue evenly on the crop fields after every harvest. Despite the fact that he had few herds of livestock, he never allowed them to graze freely on the crop fields like they did before, instead he isolated some portion of his land for grazing and also bailed fodder for the livestock. With a GPS Australian sprayer, he usually sprays herbicide as soon as the weeds emerge in the harvested fields. His reason for doing this is to reduce the weed seed bank and from the time he started adopting CA. To date, he believes he has reduced the weed seed bank by about 30%.

Even though he did not retrench some of his employees after adopting the new farming practice, his cost of production has gone down by about 55%. This was due to considerable reduction in tractor power requirement, reduced farm operations hence reduction in manpower and reduced fuel consumption. To sum it all at this point, he says, "because of CA, my blood pressure has gone down and one cannot cost that"

The yield has been on the increase and because of enormous mulch developed in the crop fields due to accumulation of crop residues, moisture retention is greatly improved and he does not worry much about rainfall pattern since he is sure to continue with his season calendar as usual thanks to in situ water harvesting property of CA. At first his neighbouring wheat farmers thought that he was irrigating his land since his crops were ever green and healthy while theirs was a total crop failure due to lack of rainfall. He says that the region, being semi arid, requires a sustainable agricultural practice to enable a farmer to acquire a harvest which would be profitable.

Information Sources

- Derpsch, R. (1998). Historical Review of No-Tillage Cultivation of Crops. MAG-GTZ Soil Conservation Project, Asuncion, Paraguay. In Proceedings, 1st. JIRCAS Seminar on Soybean Research, March 5-6 1998, JIRCAS Working Report, No. 13, 1998.

- Derpsch, R. (1999). New Paradigms in Agricultural Production. ISTRO-INFO EXTRA, Vol. 4. www.soils.wisc.edu

- GTZ (1998). Conserving Natural Resources and Enhancing Food Security by Adapting No-Tillage. An Assessment of the Potential for Soil-conserving Production systems in Various Agro-Ecological Zones of Africa. GTZ Eschborn, Tropical Ecology Support Program, TÖB F-5/e.

- Gachene, C.K.K. and Kimaru, G. (2003). Soil Fertility and Land Productivity - A guide for extension workers in the eastern Africa region. Technical Handbook No.30. Regional Land Management Unit (RELMA)/ Swedish International Development Cooperation Agency (Sida). ISBN: 9966-896-66-X.

- Goddard, T., Zoebisch, M.A., Gan, Y.T., Ellis, W., Watson, A. and Sombatpanit, S. (eds) (2008). No-Till Farming Systems. Special Publication No.3, World Association of Soil and Water Conservation, Bangkok. ISBN 978-974-8391-60-1.

- Lal, R. (1973). No-Tillage Effects on Soil Conditions and Maize Production in Western Nigeria. Plant and Soil, Vol. 40, 321-331

- Lal, R. (1983). No-Till Farming. Soil and Water Conservation and Management in Humid and Subhumid Tropics. IITA Monograph No. 2, 64 pp.

- Phillips, E.R. and Phillips, S.H. (Eds.) (1984). No-Tillage Agriculture. Principles and Practices. Van Nostrand Reinhold Co., New York, 306 pp.

- Triplett, G.B. Jr. and Dick W. A. (2008). No-Tillage Crop Production: A Revolution in Agriculture! Celebrate the Centennial [A Supplement to Agronomy Journal]. p. 153-165.