|

African armyworm (Spodoptera exempta) The African armyworm can cause serious crop losses. Armyworms may cause indirect injury to the taproot by cutting stems and/or consuming foliage above ground. |

|

|

What to do:

|

|

Gummosis (Xanthomonas campestris pv. vasculorum) It is a primarily a disease of the vascular system. It got its name from slimy gum that oozes from cut ends of infected stalks. Yellowish streaks, usually dotted with red or brownish spots are produced on the leaves near the tips. These spots often widen to a V-shape towards the leaf tip. Top rotting may result when the terminal bud is attacked resulting to shooting of the lateral buds. The disease is transmitted in infected cuttings used for seed, knife cuts and other means of physical contacts. |

|

|

What to do:

|

|

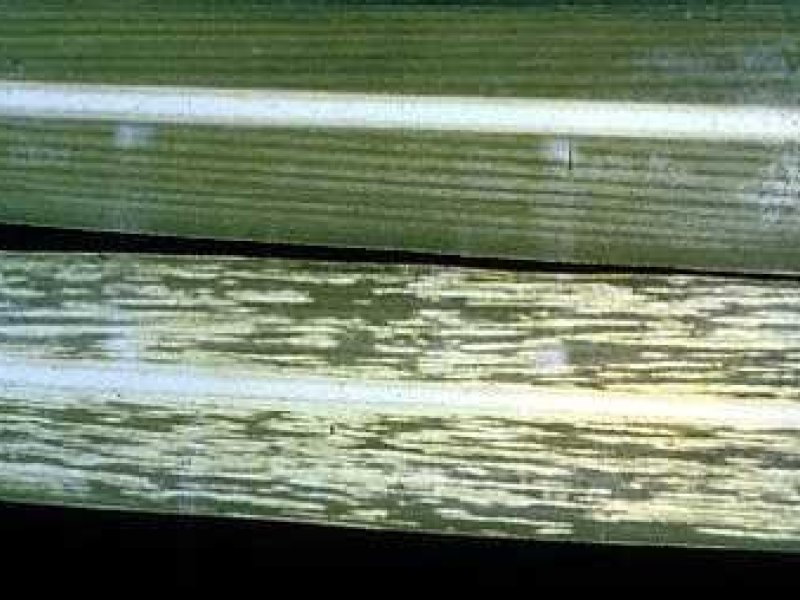

Leaf scald (Xanthomonas albilineans) It is a vascular disease but differs from gummosis in that there is no oozing of gum from cut ends. Also leaf streaks due to leaf scald are different: they begin as sharply defined, narrow, white pencil stripes, which may extend the entire leaf length.

As the leaves grow older, the streaks tend to broaden and become more diffuse. There may be only one or several streaks on a leaf. Sometimes, instead of definite streaks, the entire shoot is chlorotic to nearly white. Affected plants become stunted and in advanced disease stage some shoots or the entire stool may suddenly wilt and die. |

|

|

What to do:

|

|

Pink sugarcane mealybug (Saccharicoccus sacchari) Adult female is pinkish and it is elongated, oval to round in shape, and about 7 mm long. This mealybug is usually found in colonies on the stem beneath the sheath but is sometimes found on the stem just below ground level, on the root crowns, on the stem buds, and underneath the leaves. The leaves often turn red at the bases as a result of mealybug attack. Sooty moulds often develop in severe infestations and ants feed on honey dew excreted by the mealybugs. This mealybug is often present in very large numbers, which excrete a considerable amount of honeydew.

Damage is partially caused by the insect sucking the plant sap, which may lead to stunting and yellowing, thin canes, death of young shoots and impaired growth when mealybugs are present in high numbers, but direct damage rarely causes yield loss in sugarcane. Most damage is caused by honeydew excreted by the mealybugs and the gums exuded from the wounded parts, which interfere with the synthesis of raw sugar juice leading to filtration and clarification problems, lower quality of the syrup and reduced crystallisation. Severe attacks decrease the general vitality of the plants, which become more susceptible to diseases. |

|

|

What to do:

|

|

Pineapple disease (Ceratocystis paradoxa) It is called pineapple disease because of the characteristic odour of the rotting cuttings, which is like that of decaying pineapples. The interior of affected seed pieces becomes sooty black. Eventually the vascular bundles (tissues conducting fluids in the plant) become fibrous strands in hollow blackened core.

In contrast to red rot (which is favoured by excessive soil moisture), pineapple disease is most destructive when cane is planted in dry soil. Another major difference is that the red rot fungus is not soil-borne and infection occurs before planting, whereas pineapple disease fungus lives in the soil. |

|

|

What to do:

|

|

Ratoon stunting disease (Clavibacter xyli subsp. xyli) This disease does have overt symptoms: There is a decrease in plant vigour and decline in yields, both of which are noticeable in ratoon crops. Red spots can sometimes be seen in vascular tissues, especially in the nodes. It can be spread by infected planting material and also through mechanical operations. |

|

|

What to do:

|

|

Rats (Rattus spp.) Every 5-6 years there are explosions in rat population size, mainly attacking food crops and sugarcane. |

|

|

What to do:

|

|

Red rot of sugarcane (Glomerella tucumanensis / Colletotrichum falcatum) The fungus may infect any part of the sugarcane plant. It is most destructive as a rot of the stalk of standing cane, seed cuttings and/or stubble pieces remaining in the ground after the cane has been harvested. It produces long lesions on the leaf midribs. The lesions on the leaf midribs are dark or red. They may be short and discontinuous or long extending the length of the leaf. The centres become straw-coloured with age and are later covered with black powdery mass of spores of the fungus. However, the leaf lesions cause no serious injury to the plant but are important in the life cycle of the disease because they are sources of the spores that cause infection of the stalk. Affected plants turn yellow, shrivel and the upper leaves die. On splitting the stalk or seed cutting, the normally white or creamy-white internal tissues are reddened and the reddened area is cross-barred with white or light patches. Any sort of wounding causes a reddening of the stalk tissues next to the wound, but when diseased the characteristic red discolouration extends beyond the point of the wound. In advanced stages of rotting, the interior of the stalk darkens and the tissues shrink, leaving a cavity, which may be filled with mycelium (growth) of the fungus. The disease is spread by wind and rain. It is also spread by planting infected seed cuttings and it is enhanced by injuries by sugarcane borers and sugarcane weevils. |

|

|

What to do:

|

|

Stemborers Stemborers are the most important pests of sugarcane. Several species of stemborers attack sugarcane. The most important is the African stemborer.

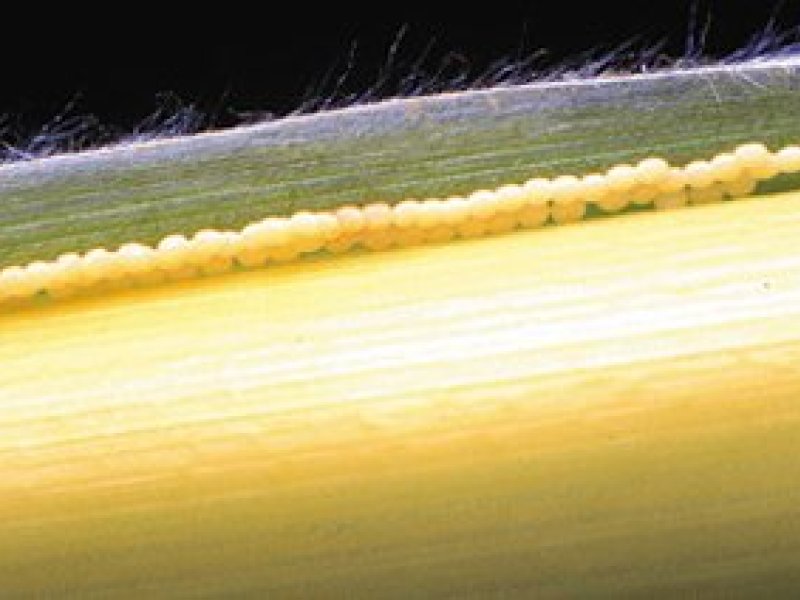

1) African sugarcane stalkborer (Eldana saccharina) Adult moth has a wingspan of 30 to 40 mm. It has elongated, pale brown forewings, each with two small spots in the centre, and whitish hind wings with a short fringe. Adult moths congregate on the cane canopy at night, they are attracted to light and so populations can be sampled using light traps. Female moths lay batches of yellow, oval eggs behind the leaf sheath or in folds of dead leaves. Eggs become pink before hatching. Young caterpillars feed on the leaves eating away the upper layers of the tissue; this damage is known as windowing. Later, they penetrate into the stalks. Caterpillars usually burrow into single internodes. When burrowing in the stem, caterpillars push their excrement outside.

Large amounts of frass are often hanging from the exit hole made by caterpillars prior to pupation. Caterpillars are light brown to dark grey coloured with brown with very small dark coloured spots. Pupation takes place in the plants, in the stem or on the leaf sheath. At emergence, the moth leaves a large emergence hole in the stalk. Attacked plants are stunted; in severe attacks they may dry up and die. When very young plants are attacked "dead heart" results, followed by tillering of the plant.

Older plants or ratoon cane have internodes bored. Crop losses are hard to assess because they vary with the age of the cane. In unstressed, maturing cane, quite high numbers of borers may be present without serious crop loss, but where infested, stressed cane is left to stand from one season to the next, the loss may be total. This stemborer also attacks maize and sorghum.

2) Spotted cane borer (Chilo sacchariphagus) It is a serious pest of sugarcane in the Indian Ocean Islands (Mauritius and Reunion), and also attacking sugarcane in Mozambique and South Africa. |

|

|

What to do:

|

|

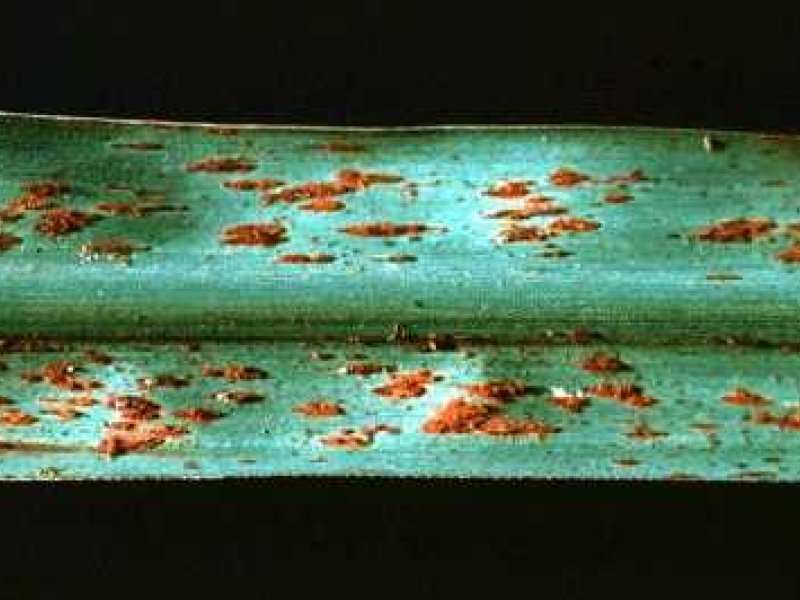

Sugarcane common rust (Puccinia melanocephala) Initial symptoms of sugarcane common rust are elongate yellowish leaf spots, 1-4 mm long. On susceptible plants, the spots increase in size and reddish-brown in colour. Typical rust pustules form on the leaves. The elongate pustules are parallel to the venation of the leaf and measure 2-20 mm by 1-4 mm. Multiple pustules on leaves give a reddish appearance to plants from a distance. |

|

|

What to do:

|

|

Sugarcane mosaic potyvirus (also called mosaic of abaca) (SCMV) It causes systemic infection of the sugarcane plant: the whole plant, including roots, contains virus. The symptoms (mosaic and/or necrosis) are observed on the leaves and sometimes the stems. Sometimes the whole plant is stunted. The classical symptoms are contrasting shades of green on a background of paler green to yellow chlorotic areas. It is aphid transmitted and also through infected planting material. |

|

|

What to do:

|

|

Sugarcane scale (Aulacaspis tegalensis) Adult scales are pear-shaped (females) to elongated (males). The scale mainly attacks stalks and leaf sheaths but can also be found on leaves as a result of crowding on the stalks. In the case of severe infestation, the cane stalks are almost entirely covered by scales. When gravid, the female's body is 1.8 mm long and 0.9 mm wide. After egg-laying, the female shrinks and loses her pink colouration. Eggs are laid under the females scale. Upon hatching the crawlers (young immature mobile stage) wander looking for a feeding site. They insert their needle-like mouthparts and suck plant sap and do not move again. They then develop a thick, waxy scale cover.

Crawlers can be dispersed considerable distances by wind or movement of vegetation by field workers and transport. This scale is a serious pest of sugarcane causing yield loss (both of canes and sugar content) and making extensive replanting necessary. Yields losses of over 30% percent have been reported in Tanzania (Bohlen, 1973). |

|

|

What to do:

|

|

Sugarcane smut (Ustilago scitaminea) The main symptom of smut is a long whip-like shoot covered with black spores contained in a silver coloured membrane. It emerges at the top of the stem in place of the inflorescence. Other symptoms include stunting and production of thin horizontal leaves. Smut is spread by infected cuttings and spores released from the whip-like shoot. Infection takes place through seed pieces and through axillary buds of the growing plant. |

|

|

What to do:

|

|

Termites (Amitermes spp., Pseudacanthotermes spp., Macrotermesspp., Odontotermes spp., Microtermes spp. and Ancistrotermes spp.) Occasionally termites can be a problem by attacking the seed pieces or the roots and stems of established plants. Yield losses can be very high. In Sudan losses of 18 % have been recorded and in Central Africa losses of 5-10% are common. In Nigeria plant germination failure of up to 28 % has been reported. The most common damage to sugar cane is the destruction of the planting material (setts). |

|

|

What to do:

|

Geographical Distribution in Africa

Geographical distribution of Sugarcane in Africa. Updated on 4 July 2019. Source FAOSTAT

General Information and Agronomic Aspects

Sugarcane provides over 50% of the world's sugar requirements as it can grow in any country where it is not exposed to frost. The main product of sugarcane is sucrose, constituting about 10% of the crop. Sucrose is a highly valued food and sweetener but also serves as a preservative for other foods. Moreover, it provides the basis for various food products and beverages.

Sugarcane is chewed in all of the producing countries because of its sweet cell juice. Sugarcane juice is obtained by pressing the sugarcanes, and is mostly used to sweeten foodstuffs, but can also be consumed as fresh or fermented juice. The by-product of sugar production - molasses - is used in distilling alcohol and as an important cattle feed additive. Sugarcane can even be produced to provide motor fuel alcohol or ethanol as is the case in Brazil. Presently, the worldwide theme is on biofuels, and sugarcane is one of the major contenders. Cane tops can be used as livestock feed.

Organic sugar cane is mostly cultivated on small farms of 0.1-3 ha. The work is carried out manually, or with the help of animals. Only ripe sugarcane is cut down during the harvest. Cut off leaves and unripe plants are left on the plot. In this way, the field is never cleared, and the soil is constantly covered by a thick layer of mulch. Such systems make sustainable cultivation of sugarcane possible, also on relatively sloping ground.

Total area in Kenya under sugarcane production in 2014 was 72,181 hectares with a total production of sugar of 6,477,651 tons (FAOSTAT, 2014). The 11 sugar factories in Kenya have a production capacity of 600,000 tons against a national consumption of 800,000 tons.. The deficiency in Kenya, is primarily, due to old technology used in sugarcane companies resulting in high cost of production, and that is why Kenya cannot compete with Sudan. Sudan is one of the biggest sugarcane producers in world and number one in Africa.

Climate conditions, soil and water management

Good site conditions are necessary for successful organic cultivation. Under natural conditions, the plant seeks its place in an eco-system amongst the canopy, and therefore needs to reach above the additional crops. Relatively wet conditions tend to cause more difficulties in an organic cultivation system than do sites that are too dry. This is due to a more involved mechanical tilling of weeds, and also to the difficulties the shoots have in developing. Altitudes of 0-1700 m and pH of 5.0-7.0 are suitable.

Ideal site conditions are met with average temperatures of 20 to 28ºC and little fluctuation between night and day. The ideal amount of rainfall is around 1500-1700 mm annually, with a drought occurring during harvesting. Harvesting during wet conditions gives a lot of transport problems. The soil should be deep, humus-rich, well aerated and drained. On black cotton soils cambered beds and ditches may be necessary.

Propagation and planting

Generally, sugarcane is vegetatively propagated with cuttings of mature stalks, and true seed is only used for breeding of new cultivars. Each cutting or seed sett usually has 2-3 buds. The cuttings are put down horizontally and covered with a thin layer of soil. The leaves and top ends of seed cane can also be removed in the field, the buds are then allowed to germinate on the standing cane stalk. When the new shoots have reached a certain length, the cane is cut into setts and planted. These pre-germinated setts are excellent planting material, but vulnerable during handling and transport and very labour intensive to produce.

Crop rotation and intercropping

In contrast to perennial field cultivation of sugarcane, the nursery fields need to follow a strict regime of crop rotation, in order to prevent infestation by soil-borne diseases and pests, such as, e.g., nematodes, sugarcane smut (Ustilago scitaminea) and red rot of sugarcane (Glomerella tucumanensis). In problem cases, treatment of the seedlings with hot water can be effective. Sugarcane smut (Ustilago scitaminea), black rot (Ceratocystis paradoxa) and nematodes can be successfully managed with a 20 to 30-minute hot water treatment at 52°C. Hot water treatment is only economically feasible for nursery stock. Heat treatment even when well done reduces germination percentage and the reduction depends on the variety being treated. Heat treated cane cannot be planted straight into commercial fields for two reasons: its germination is likely to be poor and so much cane would be involved that the treatment would be prohibitively expensive. Heat treated setts are therefore planted in nurseries which are harvested about a year later to provide planting material for the commercial fields.

The seedlings are planted in rows in pre-prepared furrows (furrow depth about 40 cm). On conventional sugarcane cultivations, the average distance between the rows is 150 cm (120 cm - 180 cm). On organic sugarcane cultivations, the best results have been achieved with double rows (40-50 cm gap between 2 single rows and 110-180 cm distance to the next double row). It is necessary to plant legumes between rows of sugarcane on newly developing organic plantations.

Every new plantation should be fertilised with organic material. The organic fertiliser must be well decomposed, so that no fires can be caused by it. It should be spread as near to the plants as possible, so that all nutrients that are released are immediately available to the plants' roots. The broad middle gap between the rows of new plantations is for the sowing of legumes. On farms with enough labour available for the manual harvest, these can be common bean or in drier areas cowpea or other Vigna species.Alternatively white clover is an excellent fixer of nitrogen and covers the soil very well, smothering most weeds.

The beans do not only supply nitrogen, but are also an important source of food, and therefore useful to the economics of the plantation. Foliage of beans or legumes should be incorporated into the soil surface for best nitrogen effect.

Seed setts are planted in a narrow planting furrow, which should have good tillage. They are covered with a thin layer of soil from the inter-row. These planting furrows can be made on flat land or on the bottom of an irrigation/drainage furrow. In wet sites, planting may be on the top of the ridge between the furrows. Irrigation water is usually applied before or immediately after planting. A nursery of one ha is needed to plant 8 to 10 ha of cane.

Recommended varieties for Kenya by zone:

| Nyanza sugar belt | Awendo/Trans Mara | Mumias/Nzoia/Busia | |||

| Variety | Yield potential T cane/ha |

Variety | Yield Potential T cane/ha |

Variety | Yield Potential T cane/ha |

| "CO 421" | 87.3 | "CO 421" | 32.2 | "CO 945" | 114 |

| "CO 331" | 93 | "CO 331" | "NCO 376" | 103.4 | |

| "CO 617" | 102.7 | "CO 617" | 180 | "CO 421" | 103.1 |

| "CO 945" | 100 | "EAK 70-97" | 156 | "EAK 69-47" | 94.9 |

| "EAK 70-97" | 109.2 | "CO 945" | 97.5 | ||

| "EAK 71-402" | 89.4 | ||||

| "EAK 69-47" | 100 |

Husbandry

Weed control is carried out manually. Where sufficient labour is available, weeding is carried out at 3-4-week intervals with 3-4 weedings per season.

As sugarcane is a heavy producer of plant material, the soil under continuous ratoon crops need heavy fertilisation in order for yields not to decrease. Phosphorus in the form of rock phosphate or single super phosphate (SSP) should be applied in heavy doses at planting (40-50 bags/ha) and same amount again for each new crop. In organic systems, nitrogen has to come from natural nitrogen fixation of legumes or in the form of compost/manure or slurry, which then also is needed in heavy applications.

Irrigation water, if necessary, is supplied every 2-4 weeks to the cane rows in the case of furrow irrigation, and to the cane on flat land or in small furrows in the case of sprinkler irrigation. When the cane grows taller, more water has to be applied, but intervals between the applications need not always be shortened.

In most cane fields the cane rows are earthed up 1-2 times by hand. In the end the cane stands on ridges separated by furrows. This practice stimulates root growth, consolidates the cane stools and improves drainage on the heavy clay soils. On the lighter textured soils it helps against early lodging of cane and can prevent erosion (if the direction of the furrows is along the contours of the land).

Diversification strategies

The ideal method is to cultivate sugarcane in a crop rotation system, yet for economical reasons, this is often difficult. Therefore, the good self-tolerance of sugarcane, the planting of legumes, the creation of sufficient compensatory tracts and niches, as well as a comprehensive fertilisation management system all have to help replace a lack of crop rotation on organic cultivations.

On older plantations, a covering layer of legumes can quickly be obtained by sowing directly after the harvest. The seeds and re-growing sugar cane will form a compact, green mass that can be lightly worked into the soil after 3 months, before the seedbed is prepared for the new sugar cane. At sites with a strong growth of weeds, it may be worthwhile planting a second type of fast growing green manure plant. For sowing it may help to break over the sugar cane and afterwards apply one or two sowings of green manure plants. The green manure plants should be competitive, and able to suppress any weeds that may appear. They should be non-climbing varieties, as these would be harmful to the sugarcane.

Directly following the harvest, rapid-growing legumes can be sown in between rows. These will die off after the sugarcane has appeared.

In areas with light soils and sufficient irrigation water, cane is intercropped, for example, with maize, groundnut or soybean. In such cases, the intercrops are planted on the ridges and the cane is planted 3-4 weeks later in the furrows. If required, irrigation furrows with a depth of 25-30 cm and a spacing of 1.10-1.30 m are made for hand-cultivated cane.

Harvesting

In Kenya, the planted sugarcane crop is ready for harvest at the age of 14 (coast) - 22 months (higher altitudes) and the ratoon crop at the age of 12 (coast) - 18 (higher altitude) months. Cut the cane as near o the ground as possible as the butt is the sugar-richest portion. To prepare for a ratoon crop, the stems will have to be trimmed down to ground level in order for new shoots to form well from their own roots.

The cane is cut and loaded manually, hand cut and grab-loaded or loaded in bundles by chains pulled by a tractor. Because the sucrose is being decomposed quickly inside the sugarcane, it must be processed relatively quickly after harvesting.

In many sugarcane growing regions, a controlled burning-off of the sugarcane fields is practised. Before the actual harvest, the foliage of the sugarcanes is set alight. Quite often, the sugarcane is again burned down after the harvest, in order to make the field easier to work. However if the fire gets out of control, the problem of too much cane being ready for the factory will occur, as it needs to reach the factory within 72 hours after harvest

Advocates of burning-off argue that: a) an increase in efficiency of sugarcane cutting of around 30% (the work is usually carried out by casual labourers at piece rates)

b) non-burnt sugar cane contains more foreign substances, making sugar processing less efficient.

c) working the soil is not hampered by the mulch layer. The mulch layer hinders the shoots, especially in wet climates

d) pests and diseases are destroyed by the fire and

e) nutrients in the ash are made easily available.

A 'green harvest' of sugarcane on the contrary is to harvest the cane without burning-off, which is practised in some sugarcane cultivation regions. Organic sugarcane cultivation consciously rejects the burning-off method in favour of a "green harvest" for the following reasons:

a) The sugar cane biomass remaining after harvesting is the basis for long-term sugar cane cultivation.

b) Mulch encourages nitrogen fixing.

c) Mulch suppresses unwanted growth.

d) In combination with the measures outlined above, this method helps to improve the humus content and the structure of the soil.

e) The burning-off method causes a high loss of nutrients and energy that is caused by carbon and nitrogen compound gases escaping.

Information on Pests

| African armyworm (Spodoptera exempta) The African armyworm can cause serious crop losses. Armyworms may cause indirect injury to the taproot by cutting stems and/or consuming foliage above ground. What to do:

|

| Stemborers are the most important pests of sugarcane. Several species of stemborers attack sugarcane. The most important is the African stemborer.

1) African sugarcane stalkborer (Eldana saccharina) Adult moth has a wingspan of 30 to 40 mm. It has elongated, pale brown forewings, each with two small spots in the centre, and whitish hind wings with a short fringe. Adult moths congregate on the cane canopy at night, they are attracted to light and so populations can be sampled using light traps. Female moths lay batches of yellow, oval eggs behind the leaf sheath or in folds of dead leaves. Eggs become pink before hatching. Young caterpillars feed on the leaves eating away the upper layers of the tissue; this damage is known as windowing. Later, they penetrate into the stalks. Caterpillars usually burrow into single internodes. When burrowing in the stem, caterpillars push their excrement outside.

Large amounts of frass are often hanging from the exit hole made by caterpillars prior to pupation. Caterpillars are light brown to dark grey coloured with brown with very small dark coloured spots. Pupation takes place in the plants, in the stem or on the leaf sheath. At emergence, the moth leaves a large emergence hole in the stalk. Attacked plants are stunted; in severe attacks they may dry up and die. When very young plants are attacked "dead heart" results, followed by tillering of the plant.

Older plants or ratoon cane have internodes bored. Crop losses are hard to assess because they vary with the age of the cane. In unstressed, maturing cane, quite high numbers of borers may be present without serious crop loss, but where infested, stressed cane is left to stand from one season to the next, the loss may be total. This stemborer also attacks maize and sorghum.

2) Spotted cane borer (Chilo sacchariphagus) It is a serious pest of sugarcane in the Indian Ocean Islands (Mauritius and Reunion), and also attacking sugarcane in Mozambique and South Africa. What to do:

|

| Sugarcane scale (Aulacaspis tegalensis) Adult scales are pear-shaped (females) to elongated (males). The scale mainly attacks stalks and leaf sheaths but can also be found on leaves as a result of crowding on the stalks. In the case of severe infestation, the cane stalks are almost entirely covered by scales. When gravid, the female's body is 1.8 mm long and 0.9 mm wide. After egg-laying, the female shrinks and loses her pink colouration. Eggs are laid under the females scale. Upon hatching the crawlers (young immature mobile stage) wander looking for a feeding site. They insert their needle-like mouthparts and suck plant sap and do not move again. They then develop a thick, waxy scale cover.

Crawlers can be dispersed considerable distances by wind or movement of vegetation by field workers and transport. This scale is a serious pest of sugarcane causing yield loss (both of canes and sugar content) and making extensive replanting necessary. Yields losses of over 30% percent have been reported in Tanzania (Bohlen, 1973). What to do:

|

| Pink sugarcane mealybug (Saccharicoccus sacchari) Adult female is pinkish and it is elongated, oval to round in shape, and about 7 mm long. This mealybug is usually found in colonies on the stem beneath the sheath but is sometimes found on the stem just below ground level, on the root crowns, on the stem buds, and underneath the leaves. The leaves often turn red at the bases as a result of mealybug attack. Sooty moulds often develop in severe infestations and ants feed on honey dew excreted by the mealybugs. This mealybug is often present in very large numbers, which excrete a considerable amount of honeydew.

Damage is partially caused by the insect sucking the plant sap, which may lead to stunting and yellowing, thin canes, death of young shoots and impaired growth when mealybugs are present in high numbers, but direct damage rarely causes yield loss in sugarcane. Most damage is caused by honeydew excreted by the mealybugs and the gums exuded from the wounded parts, which interfere with the synthesis of raw sugar juice leading to filtration and clarification problems, lower quality of the syrup and reduced crystallisation. Severe attacks decrease the general vitality of the plants, which become more susceptible to diseases. What to do:

|

| Occasionally termites can be a problem by attacking the seed pieces or the roots and stems of established plants. Yield losses can be very high. In Sudan losses of 18 % have been recorded and in Central Africa losses of 5-10% are common. In Nigeria plant germination failure of up to 28 % has been reported. The most common damage to sugar cane is the destruction of the planting material (setts). What to do:

|

| Every 5-6 years there are explosions in rat population size, mainly attacking food crops and sugarcane. What to do:

|

| Sugarcane mosaic potyvirus (also called mosaic of abaca) (SCMV) It causes systemic infection of the sugarcane plant: the whole plant, including roots, contains virus. The symptoms (mosaic and/or necrosis) are observed on the leaves and sometimes the stems. Sometimes the whole plant is stunted. The classical symptoms are contrasting shades of green on a background of paler green to yellow chlorotic areas. It is aphid transmitted and also through infected planting material. What to do:

|

| Sugarcane common rust (Puccinia melanocephala) Initial symptoms of sugarcane common rust are elongate yellowish leaf spots, 1-4 mm long. On susceptible plants, the spots increase in size and reddish-brown in colour. Typical rust pustules form on the leaves. The elongate pustules are parallel to the venation of the leaf and measure 2-20 mm by 1-4 mm. Multiple pustules on leaves give a reddish appearance to plants from a distance. What to do:

|

| Red rot of sugarcane (Glomerella tucumanensis / Colletotrichum falcatum) The fungus may infect any part of the sugarcane plant. It is most destructive as a rot of the stalk of standing cane, seed cuttings and/or stubble pieces remaining in the ground after the cane has been harvested. It produces long lesions on the leaf midribs. The lesions on the leaf midribs are dark or red. They may be short and discontinuous or long extending the length of the leaf. The centres become straw-coloured with age and are later covered with black powdery mass of spores of the fungus. However, the leaf lesions cause no serious injury to the plant but are important in the life cycle of the disease because they are sources of the spores that cause infection of the stalk. Affected plants turn yellow, shrivel and the upper leaves die. On splitting the stalk or seed cutting, the normally white or creamy-white internal tissues are reddened and the reddened area is cross-barred with white or light patches. Any sort of wounding causes a reddening of the stalk tissues next to the wound, but when diseased the characteristic red discolouration extends beyond the point of the wound. In advanced stages of rotting, the interior of the stalk darkens and the tissues shrink, leaving a cavity, which may be filled with mycelium (growth) of the fungus. The disease is spread by wind and rain. It is also spread by planting infected seed cuttings and it is enhanced by injuries by sugarcane borers and sugarcane weevils. What to do:

|

| Pineapple disease (Ceratocystis paradoxa) It is called pineapple disease because of the characteristic odour of the rotting cuttings, which is like that of decaying pineapples. The interior of affected seed pieces becomes sooty black. Eventually the vascular bundles (tissues conducting fluids in the plant) become fibrous strands in hollow blackened core.

In contrast to red rot (which is favoured by excessive soil moisture), pineapple disease is most destructive when cane is planted in dry soil. Another major difference is that the red rot fungus is not soil-borne and infection occurs before planting, whereas pineapple disease fungus lives in the soil. What to do:

|

| Sugarcane smut (Ustilago scitaminea) The main symptom of smut is a long whip-like shoot covered with black spores contained in a silver coloured membrane. It emerges at the top of the stem in place of the inflorescence. Other symptoms include stunting and production of thin horizontal leaves. Smut is spread by infected cuttings and spores released from the whip-like shoot. Infection takes place through seed pieces and through axillary buds of the growing plant. What to do:

|

| Ratoon stunting disease (Clavibacter xyli subsp. xyli) This disease does have overt symptoms: There is a decrease in plant vigour and decline in yields, both of which are noticeable in ratoon crops. Red spots can sometimes be seen in vascular tissues, especially in the nodes. It can be spread by infected planting material and also through mechanical operations. What to do:

|

| Gummosis (Xanthomonas campestris pv. vasculorum) It is a primarily a disease of the vascular system. It got its name from slimy gum that oozes from cut ends of infected stalks. Yellowish streaks, usually dotted with red or brownish spots are produced on the leaves near the tips. These spots often widen to a V-shape towards the leaf tip. Top rotting may result when the terminal bud is attacked resulting to shooting of the lateral buds. The disease is transmitted in infected cuttings used for seed, knife cuts and other means of physical contacts. What to do:

|

| Leaf scald (Xanthomonas albilineans) It is a vascular disease but differs from gummosis in that there is no oozing of gum from cut ends. Also leaf streaks due to leaf scald are different: they begin as sharply defined, narrow, white pencil stripes, which may extend the entire leaf length.

As the leaves grow older, the streaks tend to broaden and become more diffuse. There may be only one or several streaks on a leaf. Sometimes, instead of definite streaks, the entire shoot is chlorotic to nearly white. Affected plants become stunted and in advanced disease stage some shoots or the entire stool may suddenly wilt and die. What to do:

|

Information Source Links

- Acland J.D. (1980). East African Crops. An introduction to the production of field and plantation crops in Kenya, Tanzania and Uganda. FAO/Longman. ISBN: 0 582 60301 3.

- Agricultural Information Center, Nairobi (2002). Field Crops Technical Handbook

- Bohlen, E. (1973). Crop pests in Tanzania and their control. Federal Agency for Economic Cooperation (bfe). ISBN: 3-489-64826-9.

- CAB International (2005). Crop Protection Compendium, 2005 Edition. Wallingford, UK www.cabi.org

- Carnegie, A. J. M. (1991). Cane borers in Africa and recent work on Eldana saccharina. Paper presented to International Society of Sugarcane Technologists Entomology Workshop, West Palm Beach, Florida, USA, 11-15 March, 1991. In: Polszek A, ed. 1998. African Cereal Stem Borers: Economic importance, taxonomy, natural enemies and control. Wallingford, UK: CAB International.

- Dick J, (1969). The mealybugs of sugarcane. In: Williams JR, Metcalfe JR, Mungomery RW, Mathes R, eds. Pests of Sugarcane. Amsterdam, Netherlands: Elsevier, 343-365.

- Hill, D. S. (1983). Agricultural insect pests of the tropics and their control. Second edition. ISBN: 0-521-24638-5.

- Kfir, R., Overholt, W. A., Khan, Z. R. and Polaszek, A. (2002). Biology and Management of Economically Important Lepidopteran Cereal Stem Borers in Africa. Annual Review of Entomology. 47: 701-731.

- Sugarcane organic cultivation guideline, 2000, Naturland. Available also online www.naturland.de/en/

- OISAT: Organisation for Non-Chemical Pest Management in the Tropics. www.oisat.org

- Republic of Kenya, Ministry of Agriculture: Economic Review of Agriculture 2006.

- UNEP (2006). TERMITES THREATEN INFRASTRUCTURE AND FOOD SECURITY. www.unenvironment.org

- University of Florida IFAS Extension: Diseases in Sugarcane. www.edis.ifas.ufl.edu