Introduction

Hay making is the process of turning green, perishable forage into a product that can be safely stored and easily transported without getting spoilt, while keeping nutrient loss to a minimum. This involves reducing its moisture content by drying the forage in the sun. The process of drying the green crop without significant change in aroma, flavour and nutritive quality of forage is called "curing". This involves reducing the moisture content of green forages, so that they can be stored without spoilage or further nutrient loss.

Feeding hay to livestock helps reduce the amount of concentrate feeding, and thereby, the cost of feeding. Hay can be fed to sheep and goats

Suitable crops for making hay

Crops with thin stems and more leaves are better suited for haymaking as they dry faster than those with thick, pity stem and small leaves. These may include, among others:

- Oats

- Desmodium

- Lucerne

- Maize

- Sorghum

- Napier grass

- Rhodes grass

|

| Desmodium |

|

© J.O Ouda, KARI, Kenya

|

|

| Napier grass |

|

© J.O Ouda, KARI, Kenya

|

|

| Sorghum bicolor head |

|

© Li Dajue, Courtesy of Ecoport (www.ecoport.org)

|

|

| Maize |

|

© Natural Resources International Ltd.

|

Leguminous fodder crops (e.g. Cow pea and Lucerne) should be harvested at the flower initiation stage or when crown buds start to grow. Grasses and similar fodder crops should be harvested at the pre-flowering stage. At this stage, the crop has maximum nutrients and green matter. After flowering and seeding, grasses contain low nutrients. To make the process of curing easier, the fodder should preferably be harvested when air humidity is low

|

| Grass hay (left) and lucerne hay (right) made by a smallholder dairy farmer in Kenya |

|

© TP Lanyasunya, J.O Ouda, KARI, Kenya

|

Basic method of making hay

-

Forage is cut before it is fully mature (long before it has seeded) to maximize its nutritive value. Although cutting hay early will result in lower total volume, the increase in nutritive value will compensate for reduced yields.

-

Leaves are more nutritious than the stems, and so when cutting forage, it is important that it is cut with as much leaf and as little stem as possible.

-

Do not leave cut forage to dry in a moist environment, as this will encourage the growth of moulds. These can be extremely harmful to livestock and to people handling it.

-

The cut forage is laid out in the sun in as thin a layer as possible, and raked a few times and turned regularly to hasten drying.

-

Chopping forage into small pieces after drying will hasten the dying process.

-

The drying process may take between 2 to 3 days.

-

Hay should not be over dried as it may start to ferment and also become a fire hazard.

-

The dried hay should ideally be stored in bales when the moisture content is low, ideally less than 15%. This helps storage and requires less space.

Leaves are more nutritious than the stems, and so when cutting forage, it is important that it is cut with as much leaf and as little stem as possible. However, during drying, the leaf (being more brittle) will tend to shatter. Hay should therefore be handled with care, to try and minimize the amount of leaf that is lost in this way.

Crops with thick and juicy stems can be dried after chaffing to speed up the drying process and to prevent loss of nutrients.

Field curing is conducted during bright sunny weather but may result in bleaching of the forage and loss of leaves due to shattering. To avoid this, drying can be done in barns by passing hot air through the forage. Although artificial drying produces hay of good quality, it is expensive and beyond the reach of small and marginal farmer but can be attempted on a community basis in areas where there is a need, and the necessary facilities.

Storage of hay

-

Hay must be stored in a dry environment

-

Hay can be baled and stored under cover or can also be stored by creating hay stacks. These may be created in a field near the source, or close to where the hay will be required later in the year. Stacks may be covered by plastic sheets to keep out rain and prevent from exposure to excessive sun. The surface layer of a stack may also be "thatched", in the same manner as a thatched roof to a house

Box baling

|

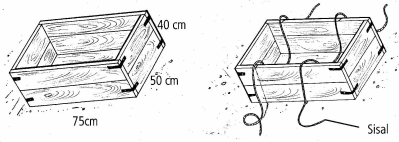

| Reduce transport costs by a third - box bale your stover |

|

© Natural Resources International Ltd.- Illustration: Joseph Kariuki

|

- Make a box with dimensions 40x50x75 cm.

- Put 2 lengths of sisal rope in the box as shown.

- Put the hay into the box and press it down tightly by jumping on it.

- Tie the box securely

- Remove the bale and stack.

|

|

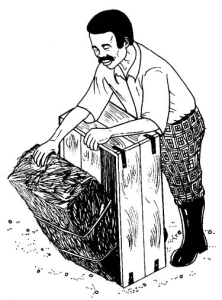

| Put in stover and jump on it until as much as possible is in the box |

|

© Natural Resources International Ltd.- Illustration: Joseph Kariuki |

|

| Tie up the box |

|

© Natural Resources International Ltd.- Illustration: Joseph Kariuki

|

|

| Remove the bale. Stack and store with ease. |

|

© Natural Resources International Ltd.- Illustration: Joseph Kariuki

|

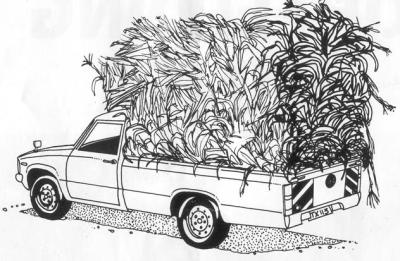

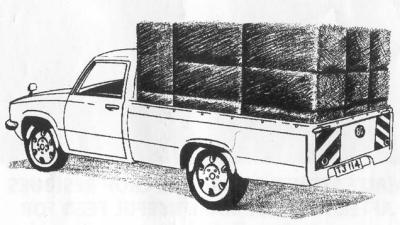

WHICH OF THESE 2 TRUCKS LOOKS AS IF IT IS CARRYING THE MOST STOVER?

|

| Truck 1 is carrying only 160 kgs of stover |

|

© Natural Resources International Ltd.- Illustration: Joseph Kariuki

|

|

| Truck 2 is carrying 260 kgs of stover |

|

© Natural Resources International Ltd.- Illustration: Joseph Kariuki

|

Problems with hay making

-

If hay is dried in a moist environment, for example during heavy rains season, mould may grow on the hay. These moulds can be extremely toxic to animals as well as the people handling it.

-

In such cases it is advisable to wait till the end of the rainy season before cutting the forage. This may lead to lower nutritional content in the hay, but this is better than toxic hay. The resultant may be supplemented with other feeds.

-

On the other hand, drying the hay too fast may lead to shattering of the delicate parts of the plant, causing a subsequent loss of nutrients.

-

To avoid this, drying can be done in barns by passing hot air through the forage. Although artificial drying produces hay of good quality, it is expensive, but can be attempted on a community basis in areas where there is a need, and the necessary facilities.

Information Source Links

- Massawe, N., Owen, E., Mtenga, L., Romney, D., Ashley, S., & Holden, S. Cut costs of feeding stover. National Resources International Ltd.

- Muyekho, F. N., Lusweti, F., Cheruiyot, D. T., & Kama, J. N. (2005). Forage crops for western Kenya. Kitale: Kenya Agricultural Research Institute (KARI).

- NR International,Livestock Production Programme (LPP). (2006). Hay Making. Retrieved February 2010, from Smallstock in Development

- Suttie, J. M. (2000). Hay and straw conservation - For small scale and pastoral conditions. FAO Plant Production and Protection Series No. 29 , p. 315.